First of all, don’t panic! Most of our products are flash frozen before transportation in accordance with the Australian Meat and Livestock guidelines. Just like meat that is transported to major supermarkets (like Coles-Worths etc), and just like seafood that has been freshly caught and processed on the boat (like in your local seafood outlet), this product has been fully processed chemical-free and snap frozen on site ready for transportation at 0°/-1°C.

WHAT DOES THIS MEAN?

Provided hygienic slaughter and cutting methods are used, the shelf-life of meat packed in this way and stored under 0°/-1°C extends storage life (up to eight weeks for beef and wild game, four weeks for lamb, and two to three weeks for pork and chicken), which is important for the export and movement of chilled meat.

Snap/Blast Freezing of chemical free products must be used to minimise any physical, biochemical, and microbiological changes affecting quality in storage. Freezing to 0°/-1°C inactivates any microbes — bacteria, yeasts, and moulds — present in food. Freshness and quality at the time of freezing affect the condition of frozen foods. If frozen at peak quality, thawed foods emerge tasting better than foods frozen near the end of their useful life. It also means the food is histamine friendly. After freezing, content must be protected with plastic film, bulk packed or vacuum-packed in plastic bags; placed inside cardboard boxes and usually frozen in these.

This product is safe to partially defrost and refreeze. You may temper the product until it remains icy (no warmer than 5°C, icy to touch), break down into your chosen preferred packaging sizes, and then safely refreeze without any repercussion. The MLA defines partially thawed meat as “meat that is still partially frozen. When you press your fingers or thumbs gently against the meat packaging, there are still some semi-hard areas.”

When meat is transported from meat processing yards, fishing vessels, poultry farms, and game meat harvesters, the flash (snap) freezing of the product allows it to sit in a tempered state in a non-fluctuating environment, ready to be transported safely.

When you buy your ‘fresh’ product from the butcher shop, Coles, or Woolworths, or a specialty grocer, the likelihood of the product having arrived at that destination frozen or at 0°/-1°C is about 95% possible. It is the most common way for the product to move around Australia without spoilage.

Meat purchased in the supermarket ‘Fresh’ meat cabinet aisle is stocked with nothing but meat that has been frozen and thawed several times over along the supply chain and in the supermarket until it is sold. Yet, consumers have no problem believing this is both fresh and safe and not realizing they have purchased meat that’s frozen and thawed several times over.

To illustrate the point further with a common real-world example: most people would think nothing of buying fresh meat at the supermarket, then refreeze.

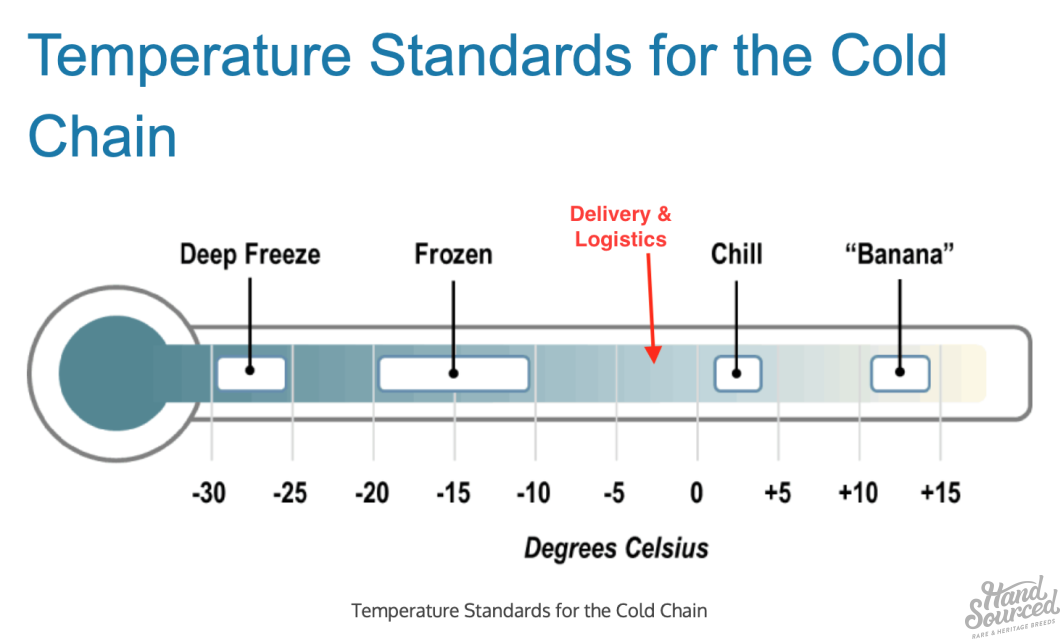

Depending on the type of product being transported through the cold chain, specific temperature standards are enforced. Five temperature standards are the most prevalent:

- Deep freeze (-25 to -30 Celsius). The coldest temperature range that can be maintained by conventional refrigerated units. This temperature range is used mostly for transporting seafood and ice cream.

- Frozen (-10 to -20 Celsius). Used for transporting frozen meat, including beef, poultry, and pork.

- Soft Frozen (0- -1 Celcius). Used for localised logistics (transport) completed in 7-10 days.

- Chill (2 to 4 Celsius). This range comprises the standard temperatures in a refrigerator and is commonly used to transport fruit, vegetables, and fresh meat as it confers optimal shelf life without freeze damage.

- Banana (12 to 14 Celsius). This temperature range is chosen for one of the world’s most-produced fruit that usually has its ripening controlled during shipping. It is also used for most tropical fruits (oranges and pineapples) and vegetables (tubers such as potatoes).

Temperature standards are easier to implement and monitor since they apply to a wide range of temperature-sensitive goods.

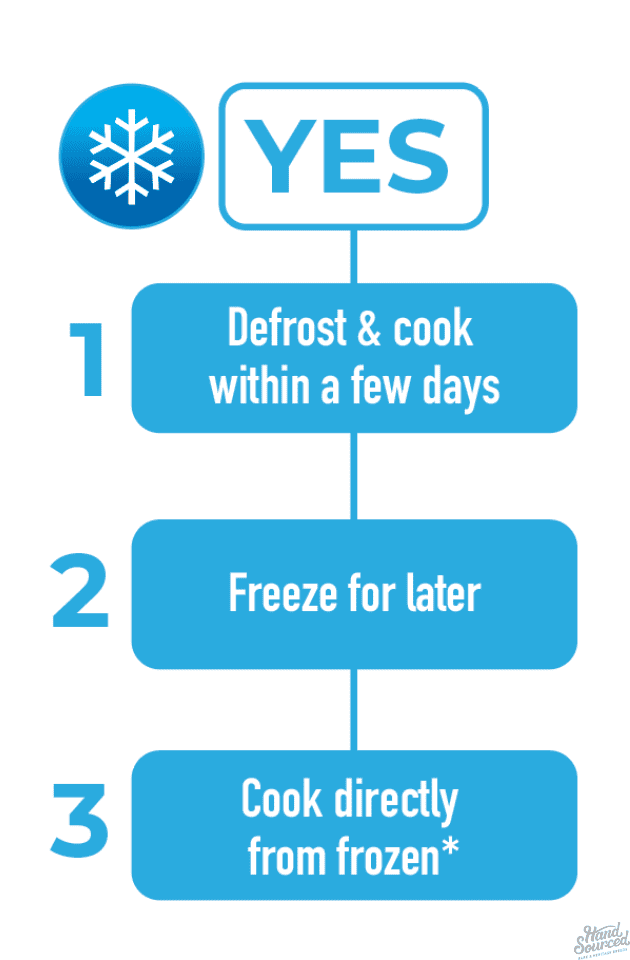

WHAT CAN YOU DO NOW?

Your product has been snap frozen once and once only. You can now handle it and cut, pack, and manage it to your liking without any concern.

Your product has been snap frozen once and once only. You can now handle it and cut, pack, and manage it to your liking without any concern.

This product is safe to partially defrost and refreeze. You may temper the product until it remains icy (no warmer than 5°C, icy to touch), break down into your chosen preferred packaging sizes, and then safely refreeze without any repercussion. The MLA defines partially thawed meat as “meat that is still partially frozen. When you press your fingers or thumbs gently against the meat packaging, there are still some semi-hard areas.”

We never sacrifice quality and constantly strive to offer the most delicious, nourishing, and ethically sourced meat and seafood. Keeping your freezer stocked and your loved ones well-fed is our passion. Meat that’s good for the earth, good for the animals, and great for you can be either fresh or flash frozen – and you’ll never find it lacking in quality.

*The links below provide some more information about transportation throughout Australia, and if you’ve got any questions at all please do not hesitate to contact me via the contact page. Enjoy your product.

Transport:

Meat stored and transported at low nonfluctuating temperature:

Frozen Food Transportation Systems Australia, Department of Agriculture, Fisheries and Forestry

https://www.agriculture.gov.au

Food and Agriculture Org (US)

https://www.fao.org/3/t0098e/T0098E02.htm#:~:text=Provided%20hygienic%20slaughter%20and%20cutting,boneless%20chilled%20meat%20from%20meatproducing

Australian Cold Chain Guidelines

https://www.afgc.org.au/wp-content/uploads/2019/07/Australian-Cold-Chain-Guidelines-2017.pdf

Handling at home or in your venue:

Specific information about chicken meat and food safety

www.chicken.org.au

Food Safety Resources

www.foodsafety.asn.au/food-safety

Leave a Reply